SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

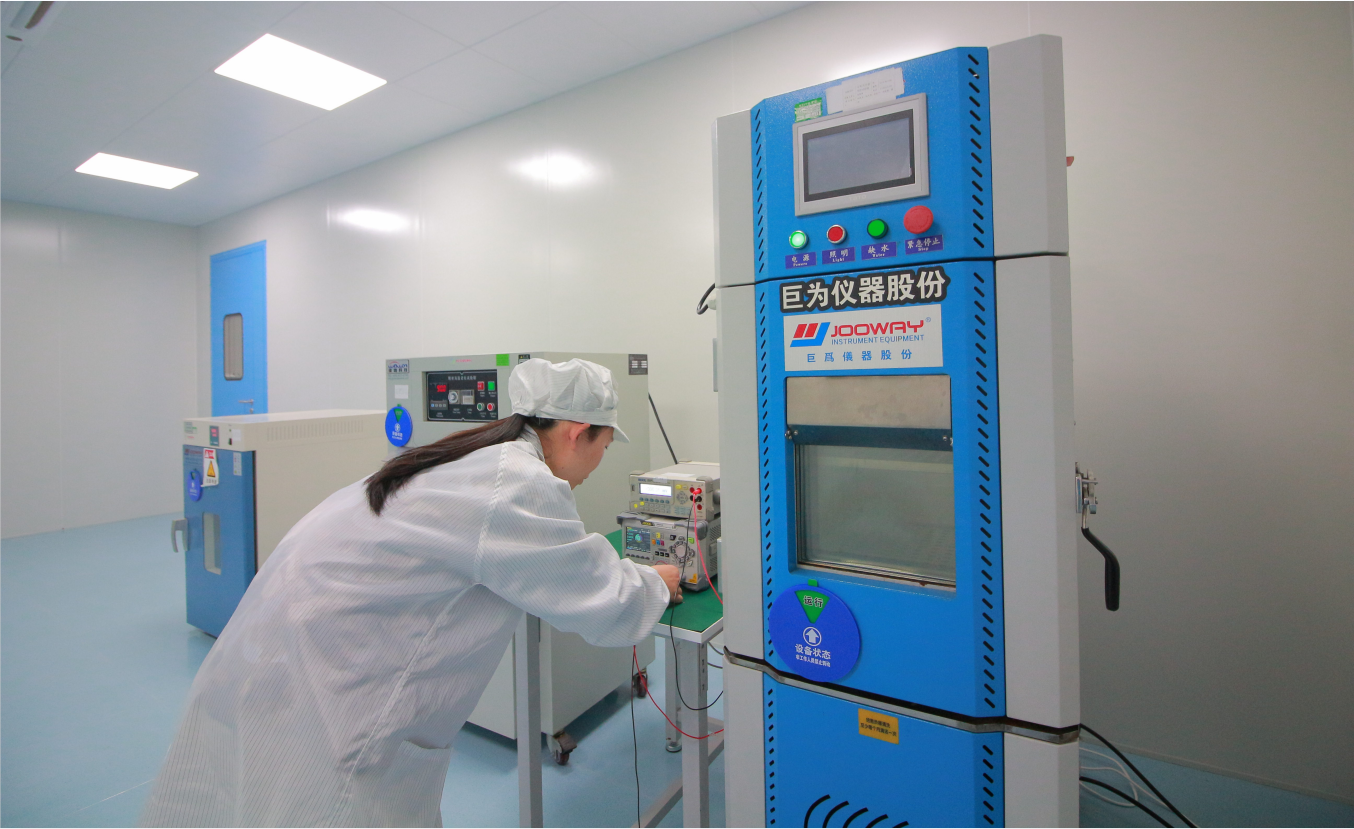

High and low temperature testing, also known as high and low temperature cycling testing, is a part of product environmental reliability testing. Most products are stored or operated in certain temperature environments. In some environments, the temperature continuously fluctuates, ranging from high to low. For example, in regions with large temperature differences between day and night or when products are repeatedly exposed to high and low temperature zones during transportation, storage, or operation. The high temperature in such environments may exceed 70°C or even higher, while the low temperature may reach -20°C or even lower. These fluctuating temperature environments can affect the product’s functionality, performance, quality, and lifespan, accelerating the aging process and shortening the product’s service life. If the product is exposed to such drastic alternating high and low temperature environments for an extended period, it needs to possess sufficient resistance to high and low temperature cycling. To evaluate the product’s performance in this aspect, it’s necessary to simulate specific environmental conditions and perform high and low temperature testing. If the test results fail to meet the specified standards, the product would need improvement based on the test findings, followed by retesting until it meets the qualifications.

The purpose of this test is to determine the ability of components, equipment, or other products to withstand the usage, transportation, or storage in high temperature environments. It measures the device’s tolerance to extreme high and low temperatures and evaluates the impact of alternating extreme temperatures on the device.

Scope of Application:

Electrical and electronic products such as electronics, components, and circuit boards, etc.

Image of High and Low Temperature Testing Equipment:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou