SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

Vibration testing is a laboratory-based method for simulating the effects of various vibration environments that products, typically electrical and electronic products, may encounter during storage, transportation, installation, and use. It is used to assess whether a product can withstand different environmental vibrations and function properly without failure.

Products suffering external vibration may lead to two types of error. One is board level solder ball breaking due to fatigue by repeated vibration stress during transportation or field operation. The other is severe structure damage caused by resonance amplification triggered by vibration stress as a result of fixation method or structural design natural frequency.

Purpose: Vibration testing allows for the analysis and evaluation of product reliability before formal production, reducing the probability of defective products and ensuring compliance with design and functional requirements.

Failure Mode:

Scope of Application:

Electrical and electronic products.

Vibration Testing Classification:

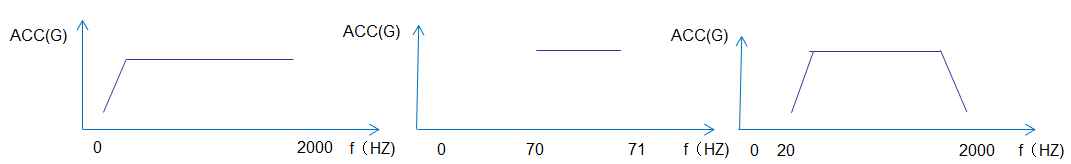

The most common types of vibration testing services conducted by vibration test labs are Sinusoidal and Random. Sinusoidal or Sine Vibration Testing is one of the more common types of vibration testing services performed by labs., aiming to simulate vibrations such as rotation, pulsation, and oscillation (occurring in ships, aircraft, vehicles, and spacecraft) as well as analyze the resonant frequency and verify the presence of resonant points in the product structure. The types of Sinusoidal Vibration Testing are Sine Sweep Vibration Testing and Sine Dwell Vibration Testing, depending on the frequency range, amplitude, and test duration. Random Vibration, on the other hand, aims to simulate the overall structural seismic strength of a product and the transportation environment in its packaged state. The severity of the test depends on the frequency range, GRMS, test duration, and axis.

1.Sinusoidal Vibration Testing: This test applies sinusoidal vibration to the test specimen, which can be either sine sweep or sine dwell vibration testing.

2.Random Vibration Testing: This test applies random vibration to the test specimen and can be classified into broadband random vibration testing and narrow-band random vibration testing based on the frequency bandwidth.

Image of Testing Equipment:

Vibration table parameters: maximum thrust, maximum acceleration, maximum velocity, maximum displacement, vibration table size and weight, table resonance frequency, vibration table frequency range.

Sample Parameters: sample dimensions, sample weight, test parameters.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou