SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

A die must be linked with the substrate to fulfill its intended function; a wire bonding is to connect the signal from a die to the substrate.

Scope of Application:

PCB development and packaging projects;

Rework of rejected ICs sample preparation, backside sample preparation;

Push and pull test (ball shear/wire pull/solder ball shear/die shear);

Wire Bonding/Molding/Capping;

Varieties of wire bonding methods: driver IC, COB, Chip-To-Chip, Ball Mounting.

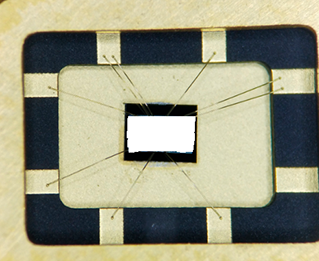

Testing Images:

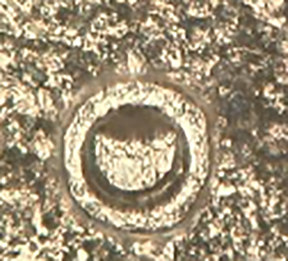

Stud Bumping: Mounting a ball on a solder pad, primarily bonded with Au wires.

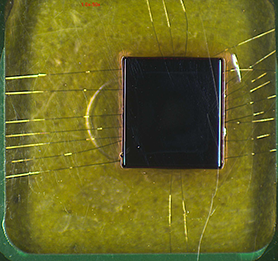

Backside Sample Preparation: A ball-type joint at the first connection and a wedge joint at the second connection. The placement of bonding wire takes the center of the ball-type joints. Mainly bonded with Au and copper wires.

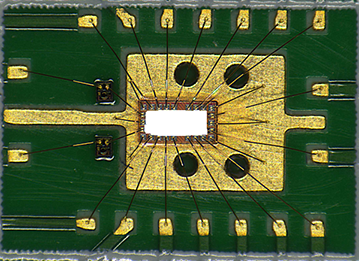

COB Bonding: Both the first and second joint are wedge-shaped, so the bonding direction has to be parallel to the pad. Aluminum (Al) wire is normally used.

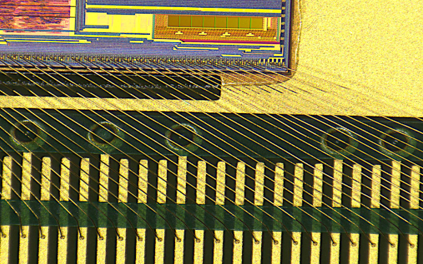

Driver IC Bonding:

Ceramic Package:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou