SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

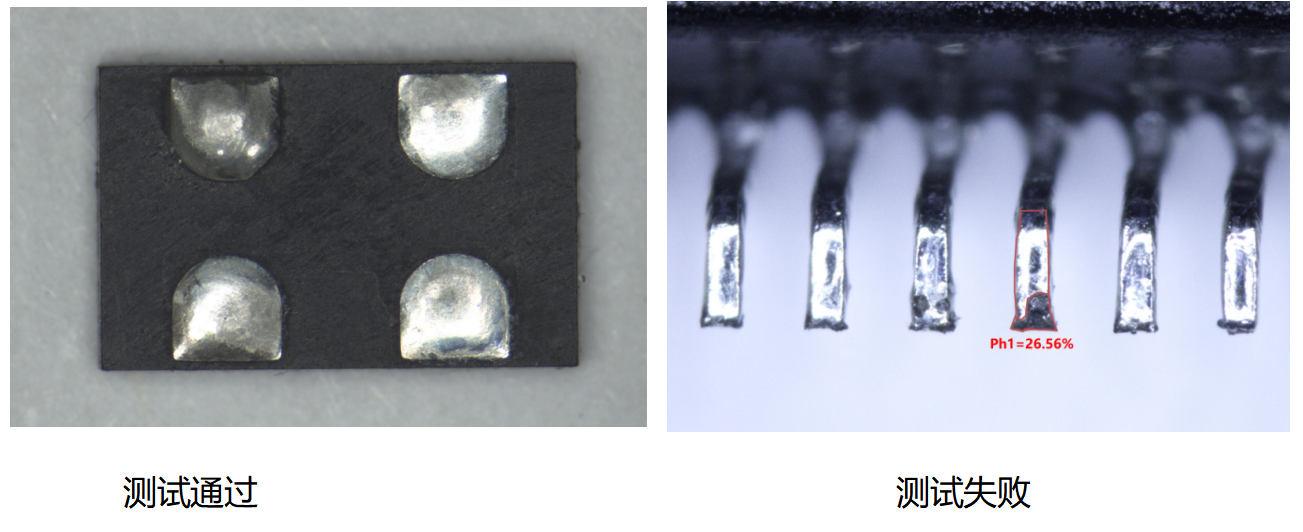

描述: 根据可焊性测试的相关标准,模拟芯片上机过程以检测芯片管脚的上锡程度是否达到焊接标准的要求,以此来判断样品管脚能否正常的焊接。

我们的优势:可支持BGA在内的所有封装可焊性测试,能模拟SMT温度曲线焊接测试,快速响应结果。

可焊性测试图片:

注:引脚测试端被新的焊料层覆盖面积超过95%以上为合格

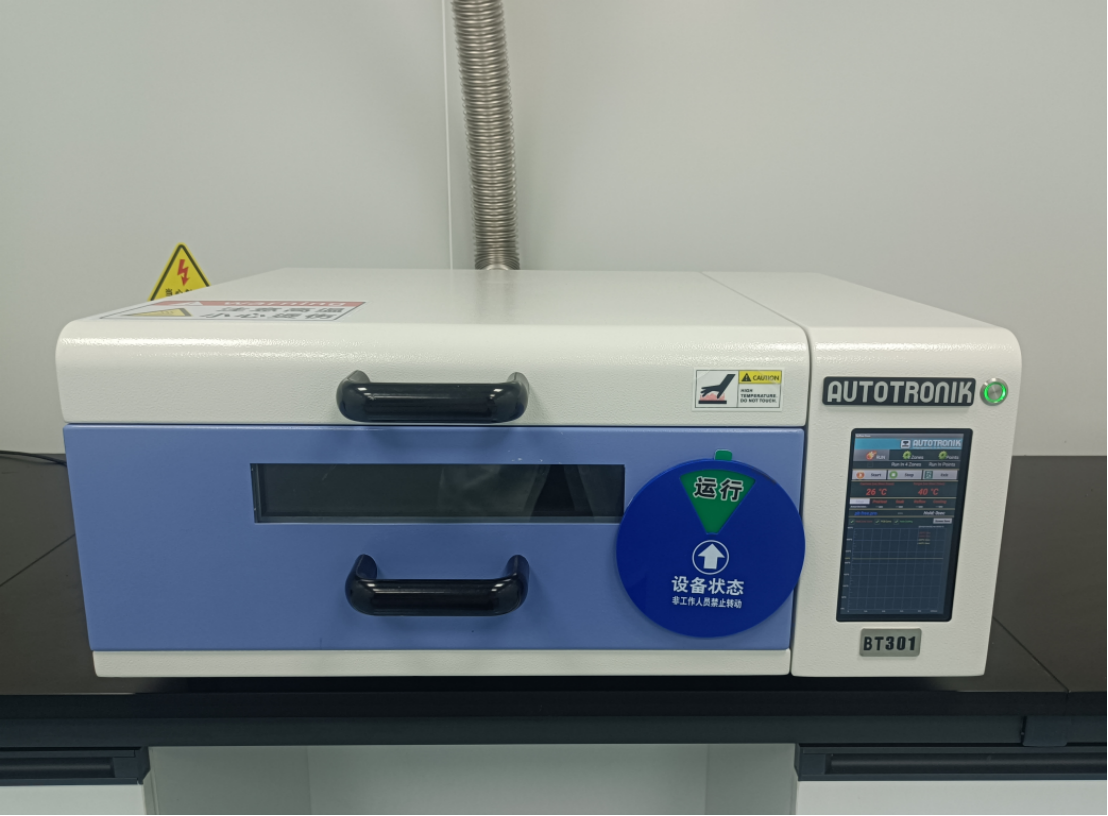

回流曲线:

可焊性测试设备图片:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou